Boron carbide, Silicon carbide or other materials Vacuum Sintering Furnace

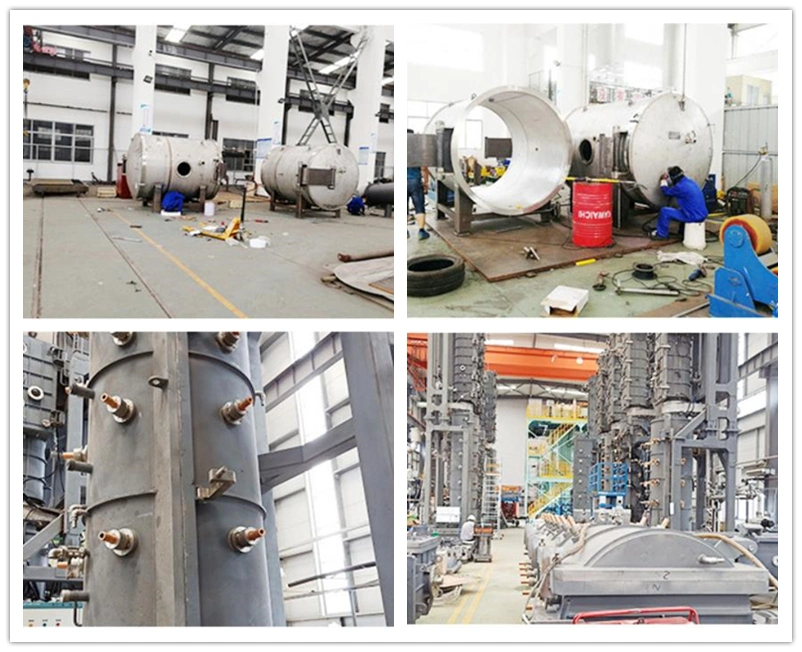

About ShengmiaoHenan Shengmiao Instrument Co., Ltd. is China's leading supplier offering a wide variety of lab instrument products. With over 28 years of expertise in metallurgical industry, the company is specialized for various industrial vacuum furnace manufacturing and marketing.

Our furnaces include heat treatment vacuum furnaces such as vertical high temperature graphitization furnace , horizontal high temperature graphitization furnace, lab graphitization furnace, high temperature carbonization furnace , silicon carbide vacuum sintering furnace, lab vacuum sintering furnace.

We keep making effort to provide superior products and service for our customers home and aboard. With the know-how of heat treatment and vacuum furnace equipment, we will provide globe customers the most suitable vacuum furnace equipment.

Shengmiao has a group of experts in the field of metallurgical industry . All of our technicians are trained engineers that have worked in various furnaces or within graphite manufacturers in the past. We know all of the vacuum furnaces. Our experienced engineers offer an all-round support to the customers. Our products have been exported to Europe, Asia, Africa, South America and Middle Eastern countries, which enjoys good reputation.

Our Competitive Advantages

Powerful R&D Strength:

Devoted to Metallurgical Industry R&D and Manufacture with 28 Years of Expertise;

Full Range of Products:

Meet and Exceed the Challenges of Thousands of applications, and Continue to be Innovated.

ISO 9001:2015 certified; Providing 100% Inspection and Reporting

Silicon Carbide Vacuum Sintering Furnace

Applications: This equipment is suitable for vacuum sintering and atmosphere pressureless sintering of boron carbide, silicon carbide or other materials.

| Unit/Model Parameter Index | Experimental Furnace type | Production furnace type | |||||

| SJL-S | SJL-45 | SJL-50 | SJL-50MAX | SJL-60 | SJL-75 | ||

| Crucible effective volume | mm | 300*300*400 | 450*450*750 | 500*500*1200 | 500*500*1500 | 600*600*2000 | 750*750*2000 |

| Heating Method | / | Isostatic pressure graphite cage heating (resistance heating) | |||||

| Way to control | / | manual + automatic + Remote mobile operation | |||||

| Loading volume | L | 36 | 151 | 300 | 375 | 720 | 1125 |

| Loading | g | Loading area volume * product density | |||||

| Power | KW | 100 | 165 | 250 | 300 | 400 | 550 |

| Cold ultimate vacuum | Pa | Cold state 5Pa(Diffusion pump to cold state -2) | |||||

| Common working temperature | ºC | 2300 | 2300 | 2300 | 2300 | 2300 | 2300 |

| Higher operating temperature | ºC | 2400 | 2400 | 2400 | 2400 | 2400 | 2400 |

| Temperature difference in constant temperature zone | ºC | ±5 | ±5 | ±5 | ±5 | ±5 | ±5 |

| Working atmosphere in the furnace | / | Vacuum or inert gas protection (micro positive pressure) | |||||

Main Features:

1to1 standard structure (one set of power supply, one set of furnace body)

Maximum operating temperature: 2350ºC, common temperature 2300ºC, common constant temperature zone size (600MM X600MMx 1600MM, 500mm x500mm X1300mm). The size can be customized according to customer's requirements.

Temperature uniformity: ≤±10ºC;

Temperature control method: automatic; manual; thermocouple temperature measurement from room temperature to 1200 degrees; high temperature measurement using imported infrared thermometer; low temperature and high temperature automatic switching.

Security: double protection with explosion-proof port and pressure relief valve, which is safe and reliable

Automation: One-button automatic replacement of atmosphere in the furnace; automatic detection of water and gas; automatic temperature control throughout the heating process

Control accuracy: ±5ºC

Cold ultimate vacuum: 3Pa

Working temperature: 2250ºC (argon gas atmosphere)

Design temperature: 2350ºC (argon gas atmosphere)

Heating rate: ≥10ºC/min (full load, atmosphere, below 1500ºC)

≥5ºC/min (full load, atmosphere, below 1800-2300ºC)

Product advantages:

1.Fully automation with one-key replacement system (vacuum in the furnace; argon gas filling process), Automatic monitoring of water and electricity during the whole process of operation; Touch screen simulation can observe the operating status of the equipment at any time. The equipment alarm indication, heating curve, switch machine Operations all can be viewed and operated on the touch screen.

2. The materials are authentic and reliable. The furnace body is made of 304 stainless steel, which is built in strict accordance with the pressure vessel standard, and has good corrosion resistance and airtight performance. The insulation materials are made of high-purity graphite felt, which is durable. All electrical components are imported or domestic top brands with reliable operation.

3. The automatic explosion-proof valve is installed in the furnace body with high security and reliability; The sensor part is equipped with a flow switch separately to monitor the water flow in real time. The power supply sets over-current protection and over-voltage protection strictly and effectively as required.

Customer Visiting