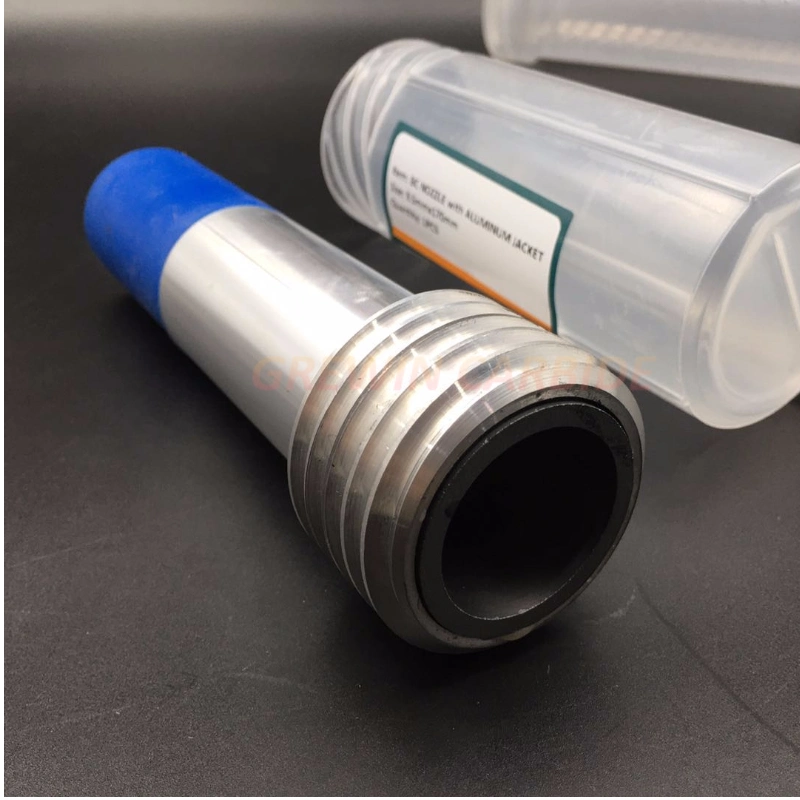

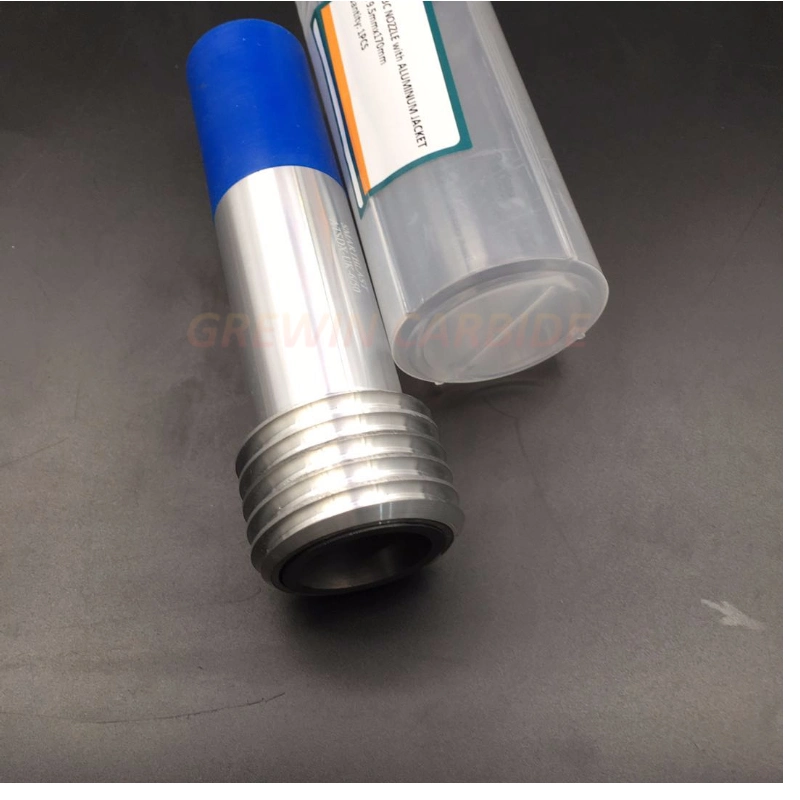

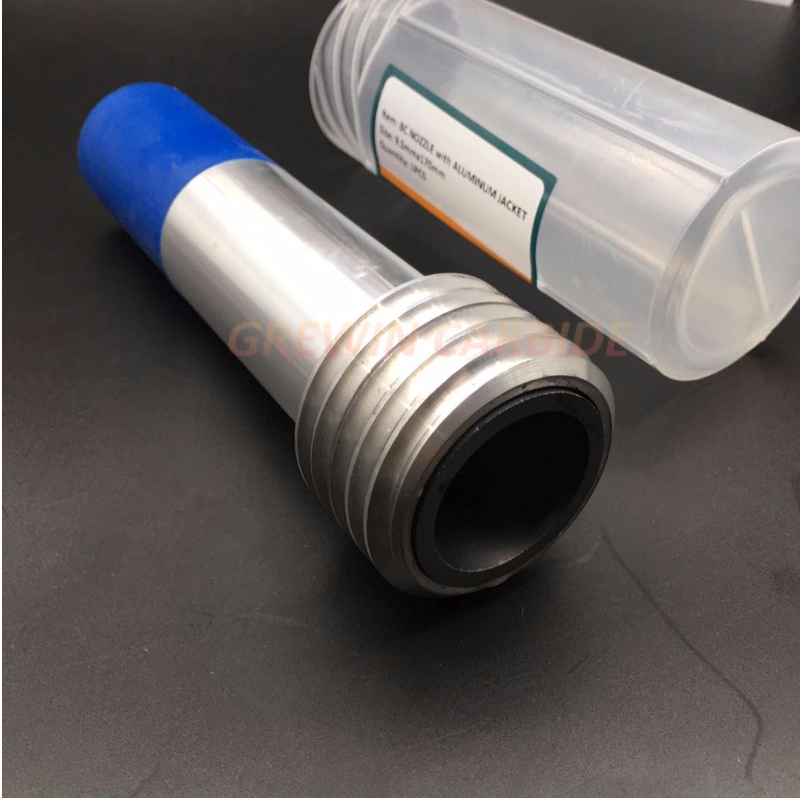

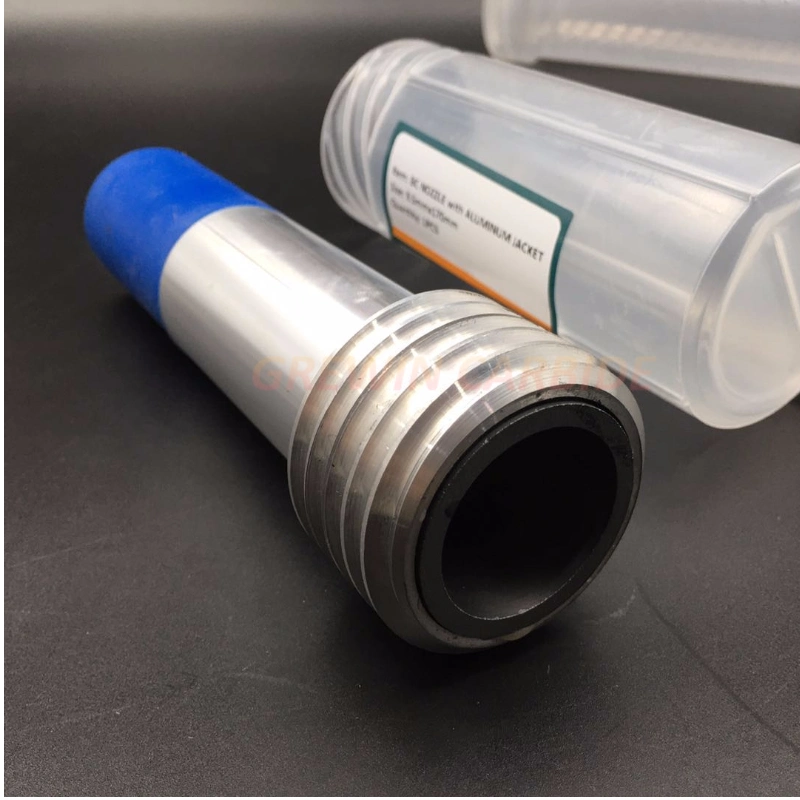

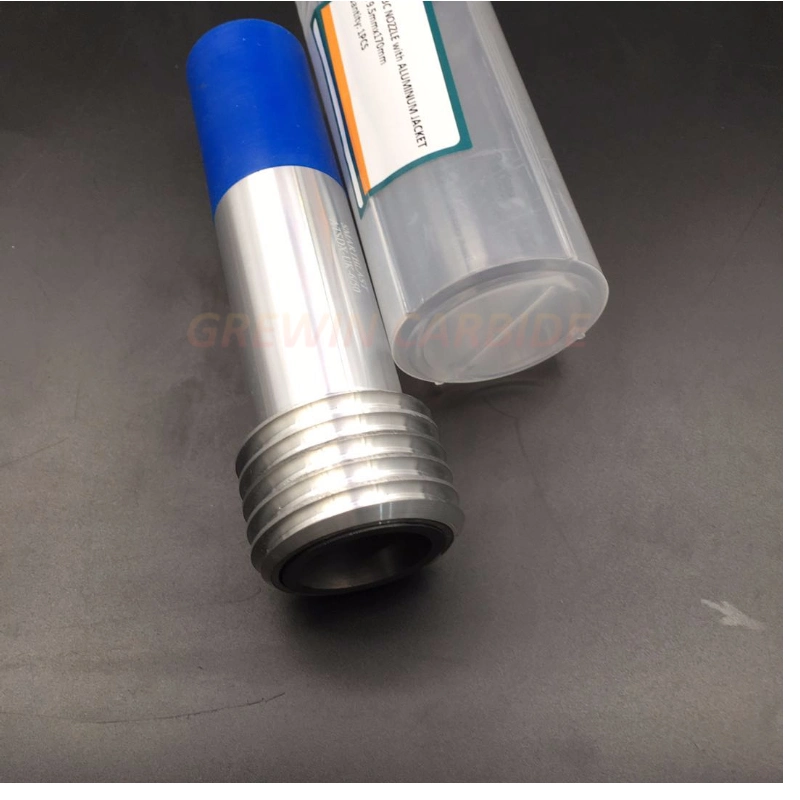

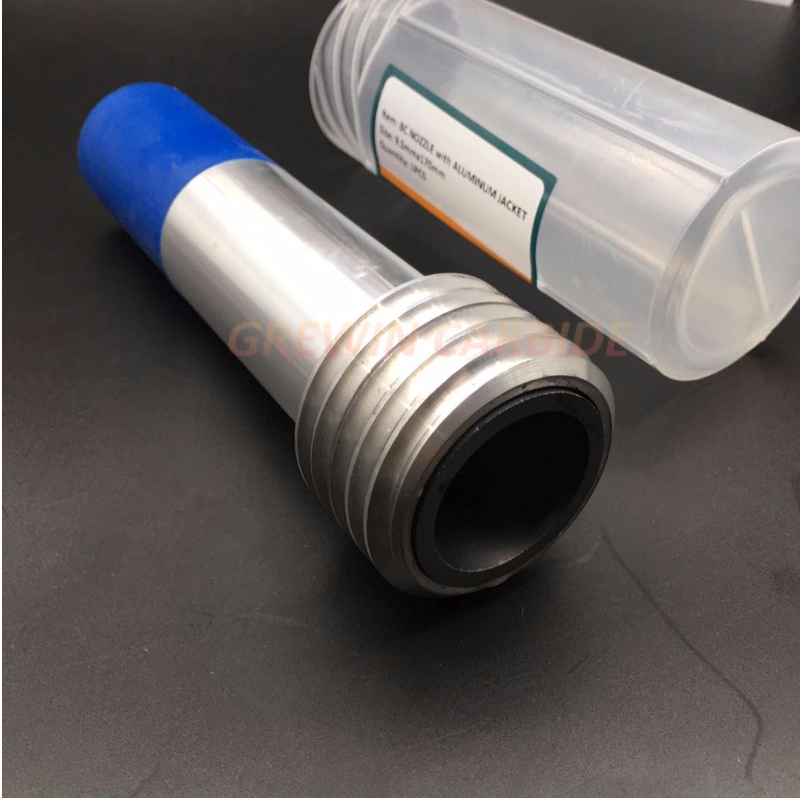

Tungsten Carbide Nozzles for Oil/Gas Drilling

Grewin supply sandblast nozzles with regular types of straight bore and venturI bore, such as boron carbide nozzles, silicon carbide nozzles, tungsten carbide nozzles and ceramic ones.

1. Boron carbide sand blasting nozzles, they have a service life 4-7times of sintered tungsten carbide nozzles, but their shock resistance is not as that of sintered carbide nozzles, so are suitable to serve under wear, stable atmospheric pressure and medium shock.

Specification:

Grind resistant, do not active with acid, low & high temperature resistance,

The density> =2.46g/cm3;

Hardness> =3500kgf/sqm, bending resistance: ≥ 400Mpa

Melting point: 2450degree

And now boron carbide nozzle is instead of hardness alloy, Tungsten carbide nozzle, silicon carbide sandblasting nozzle.

The working life of boron carbide nozzle is 500-1000H

The size can be customized as per drawing

2. sintered tungsten carbide, products including various sand blasting nozzle, high-pressure water spray nozzle, high-pressure water cutting nozzle, bars, sheets, sealing rings, punching die blocks, glass cutters, etc.

We are able to produce tubes with diameter of 200mm and length of 300mm, for rings, size can be diameter up to 320mm and length to be 200mm.

advantages on Tungsten carbide sand blasting nozzles :

1. very high hardness.

2. stable working effort during blasting.

3. long sizes are accetable.

4. very good prices with quite fast delivery.

5. special sizes with drawing are acceptable.

3. Silicon carbide sand blasting nozzles have middle wear resistance and anti-shock ability compared with boron carbide and tungsten carbide, and much lighter than tungsten carbides.

Grade Recommend of Tungsten carbide sand blasting nozzles :

Our Services

More than 2000 products are available. Assembly line production, high standard and strict requirements.

OEM Services Offered

Customized Tools Offered

Free laser marking on tools and boxes Offered

Fast delivery time and Convenient Transportations.We have discount on shipping cost from our courier companies, such as FEDEX,DHL,TNT, UPS etc.

Company Information

Zhuzhou Grewin Tungsten Carbide Tools Co., Ltd is located in hometown of Chinese carbide industry - Zhuzhou city. The company has more than 20 years' experience in manufacture, design and sale of various kinds of carbide products, main products include: carbide end mills, carbide rods, indexable inserts, brazed inserts, wire drawing dies, forging dies, wood working tools, saw tips, mining buttons, etc

The company has passed ISO 9001: 2008 quality system, possesses advanced production equipments, complete testing instruments, strong R&D center and QC teams.

With excellent quality, strong technical support, and good after sales service, Grewin Carbide brand products are sold to more than 50 countries in the world, such as Europe, USA, south east Asia, middle east, south America, etc.

The company is dedicated to " WE GROW, WE WIN". Grewin Carbide is growing up with the World's carbide technology, to meet the demand of our customers from all over the world.

Grewin supply sandblast nozzles with regular types of straight bore and venturI bore, such as boron carbide nozzles, silicon carbide nozzles, tungsten carbide nozzles and ceramic ones.

1. Boron carbide sand blasting nozzles, they have a service life 4-7times of sintered tungsten carbide nozzles, but their shock resistance is not as that of sintered carbide nozzles, so are suitable to serve under wear, stable atmospheric pressure and medium shock.

Specification:

Grind resistant, do not active with acid, low & high temperature resistance,

The density> =2.46g/cm3;

Hardness> =3500kgf/sqm, bending resistance: ≥ 400Mpa

Melting point: 2450degree

And now boron carbide nozzle is instead of hardness alloy, Tungsten carbide nozzle, silicon carbide sandblasting nozzle.

The working life of boron carbide nozzle is 500-1000H

The size can be customized as per drawing

2. sintered tungsten carbide, products including various sand blasting nozzle, high-pressure water spray nozzle, high-pressure water cutting nozzle, bars, sheets, sealing rings, punching die blocks, glass cutters, etc.

We are able to produce tubes with diameter of 200mm and length of 300mm, for rings, size can be diameter up to 320mm and length to be 200mm.

advantages on Tungsten carbide sand blasting nozzles :

1. very high hardness.

2. stable working effort during blasting.

3. long sizes are accetable.

4. very good prices with quite fast delivery.

5. special sizes with drawing are acceptable.

3. Silicon carbide sand blasting nozzles have middle wear resistance and anti-shock ability compared with boron carbide and tungsten carbide, and much lighter than tungsten carbides.

Grade Recommend of Tungsten carbide sand blasting nozzles :

| Grade | Equal to ISO Category Number | Performance | Uses | ||

| Density | Bend Strength | Hardness | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG3 | K01 | 14.9-15.3 | 1180 | ≥90.5 | sand-blasting nozzlesQualified for fine turning and half-fine turning when cast iron, non-ferrous metal, alloys as well as non-alloy materials cutting consecutively. Can make wire drawing of steel and non-ferrous metal. Also qualified for sand-blasting nozzles. |

| YG3X | K01 | 15.1-15.4 | ≥1300 | ≥91.5 | |

| YG6X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Qualified for machining of chilled cast iron, alloy cast iron, refractory steel and alloy steel. Also Qualified for the machining of common cast iron. |

| YG6A | K10 | 14.7-15.1 | ≥1580 | ≥91.0 | |

| YG6 | K20 | 14.7-15.1 | ≥1670 | ≥89.5 | Qualified for finish machining and semi-finish machining for the cast iron, non-ferrous metal, alloy and unalloyed materials. Also qualified for wire drawing for the steel and non-ferrous metal, electric drill for geology use and steel drill etc. |

| YG8 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Qualified for rough machining of cast iron, non-ferrous metal, nonmetal materials, drawing of steel, non-ferrous metal and pipes, various drills for geology use, tools for machine manufacture and wearing parts |

Nozzle Material | Steel Grit/Shot | Sand | Aluminum Oxide |

Aluminium | 20-40 | 10-30 | 1-4 |

Tungsten Carbide | 500-800 | 300-400 | 20-40 |

Silicon Carbide | 600-1000 | 400-600 | 50-100 |

Boron Carbide | 1500-2500 | 750-1500 | 200-1000 |

Our Services

More than 2000 products are available. Assembly line production, high standard and strict requirements.

OEM Services Offered

Customized Tools Offered

Free laser marking on tools and boxes Offered

Fast delivery time and Convenient Transportations.We have discount on shipping cost from our courier companies, such as FEDEX,DHL,TNT, UPS etc.

Company Information

Zhuzhou Grewin Tungsten Carbide Tools Co., Ltd is located in hometown of Chinese carbide industry - Zhuzhou city. The company has more than 20 years' experience in manufacture, design and sale of various kinds of carbide products, main products include: carbide end mills, carbide rods, indexable inserts, brazed inserts, wire drawing dies, forging dies, wood working tools, saw tips, mining buttons, etc

The company has passed ISO 9001: 2008 quality system, possesses advanced production equipments, complete testing instruments, strong R&D center and QC teams.

With excellent quality, strong technical support, and good after sales service, Grewin Carbide brand products are sold to more than 50 countries in the world, such as Europe, USA, south east Asia, middle east, south America, etc.

The company is dedicated to " WE GROW, WE WIN". Grewin Carbide is growing up with the World's carbide technology, to meet the demand of our customers from all over the world.