Boron Carbide B4C Sand Blasting Gun Nozzles, More Specifications Customizable

The hardness of boron carbide is only secondary to diamond and CBN. The density of the boron carbide products produced by us is close to its academic density 2.52g/cm3. We not only supply high quality high purity boron carbide powder, but also provide customized boron carbide B4C nozzles with longer service life.

Its advantages are: longer service life, high hardness, high wear-resistance, high impact resistance, anti-corrosion, lower cost per use, reducing down time. It's the ideal material for sandblasting nozzle and mechanical seal.

Boron carbide can be used to manufacture gun nozzles in the arms industry, which is extremely hard and wear-resistant, no reaction with acid-base, high/low temperature resistance, high pressure resistance, crystal system: hexagonal, density: 2.52g/cm3, Mohs hardness: 9.36, microhardness 5400-6300kg/mm2, bending strength ≥400Mpa, melting point: 2450ºC. Because it has the characteristics of wear resistance and high hardness, Boron Carbide Sandblasting Nozzle will gradually replace the known tungsten carbide and silicon carbide, silicon nitride, alumina, zirconia and other materials sandblasting nozzle in the future.

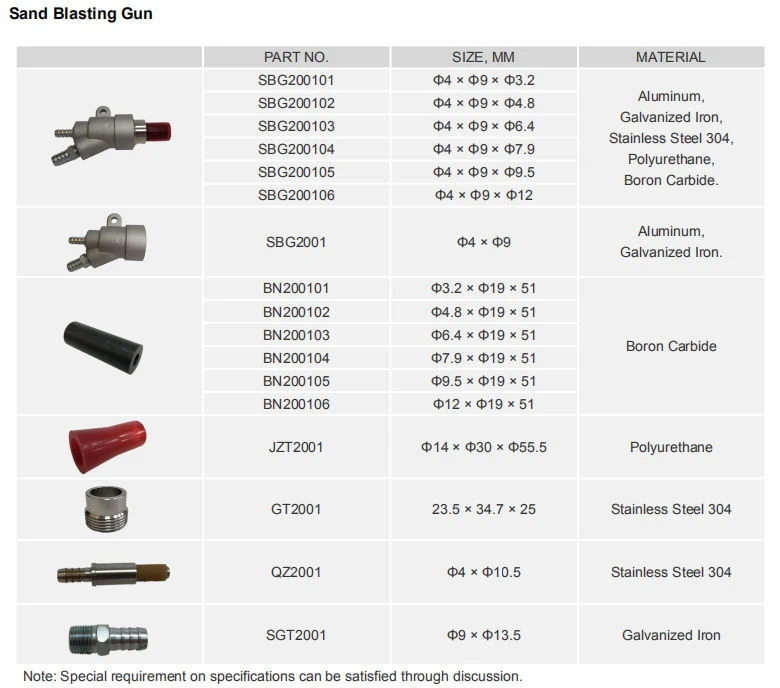

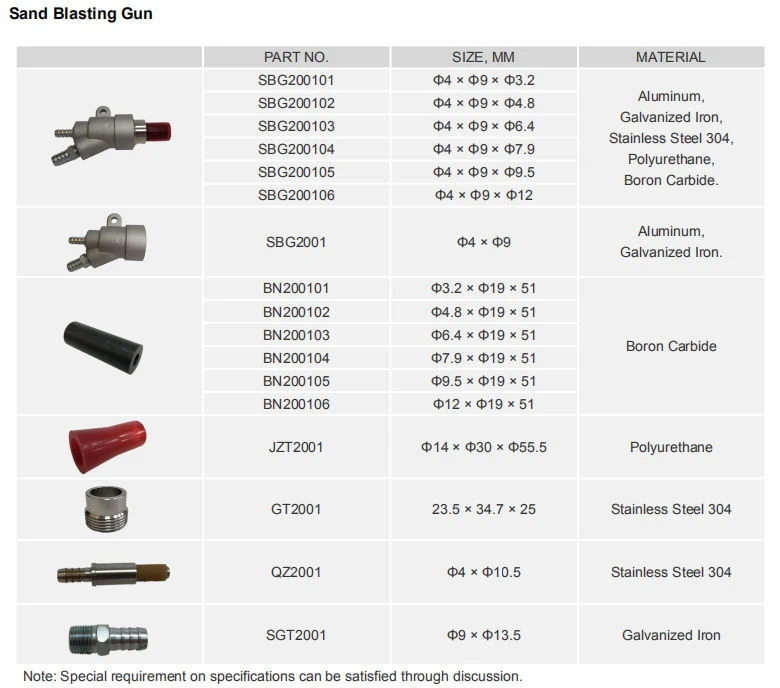

Note: Special requirement on specifications can be satisfied through discussion.

Note: Special requirement on specifications can be satisfied through discussion.

Note: Special requirement on specifications can be satisfied through discussion.

Note: Special requirement on specifications can be satisfied through discussion.

Note: Special requirement on specifications can be satisfied through discussion. We can design and manufacture complex shapes according to customers' requirements. Welcome to discuss with us about the drawings.

More boron carbide sandblasting gun nozzles for your reference.

The hardness of boron carbide is only secondary to diamond and CBN. The density of the boron carbide products produced by us is close to its academic density 2.52g/cm3. We not only supply high quality high purity boron carbide powder, but also provide customized boron carbide B4C nozzles with longer service life.

Its advantages are: longer service life, high hardness, high wear-resistance, high impact resistance, anti-corrosion, lower cost per use, reducing down time. It's the ideal material for sandblasting nozzle and mechanical seal.

Boron carbide can be used to manufacture gun nozzles in the arms industry, which is extremely hard and wear-resistant, no reaction with acid-base, high/low temperature resistance, high pressure resistance, crystal system: hexagonal, density: 2.52g/cm3, Mohs hardness: 9.36, microhardness 5400-6300kg/mm2, bending strength ≥400Mpa, melting point: 2450ºC. Because it has the characteristics of wear resistance and high hardness, Boron Carbide Sandblasting Nozzle will gradually replace the known tungsten carbide and silicon carbide, silicon nitride, alumina, zirconia and other materials sandblasting nozzle in the future.

| Service Life | |||

| Nozzle Material | Service life(h, by time) | ||

| Steel grit/shot | Silica sand | Brown aluminium oxide | |

| Alumina | 20-40 | 10-30 | 1-4 |

| Tungsten Carbide | 500-800 | 300-400 | 20-40 |

| Silicon Carbide | 600-1000 | 400-600 | 50-100 |

| Boron Carbide | 2000-2500 | 1000-1500 | 500-1000 |

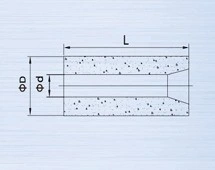

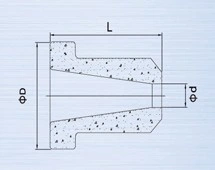

| Specifications | ||||

| Item | Specifications(mm) | ||

| I. D Φd | O. D ΦD | Length L | ||

| BCN-1301 | 2-14 | 16-37 | 10-110 | |

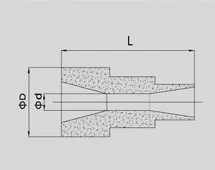

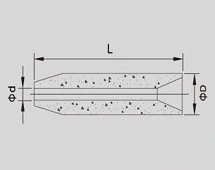

| Specifications | ||||

| Item | Specifications(mm) | ||

| I. D Φd | O. D ΦD | Length L | ||

| BCN-1302 | 3-14 | 16-30 | 50-110 | |

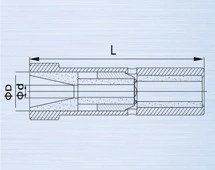

| Specifications | ||||

| Item | Specifications(mm) | ||

| I. D Φd | O. D ΦD | Length L | ||

| BCN-1303 | 6.4-11 | 30 | 10-110 | |

| Specifications | ||||

| Item | Specifications(mm) | ||

| I. D Φd | O. D ΦD | Length L | ||

| BCN-1304 | 0.8-2 | 6-10 | 10-80 | |

| Specifications | ||||

| Item | Specifications(mm) | ||

| I. D Φd | O. D ΦD | Length L | ||

| BCN-1305 | 6.4-11 | 19-30 | 145-210 | |

More boron carbide sandblasting gun nozzles for your reference.