Product Description

Item | Parameter |

Name | Nano silicon carbide ceramic powder |

Purity | >97.0% |

Free silicon | <0.2% |

Total oxygen content | <0.61% |

Crystal form | Cubic structure |

Average granularity | 60nm |

Specific surface area | 29m2/g |

Apparent density | 0.05g/cm3 |

Appearance | Gray Green |

Product Performance

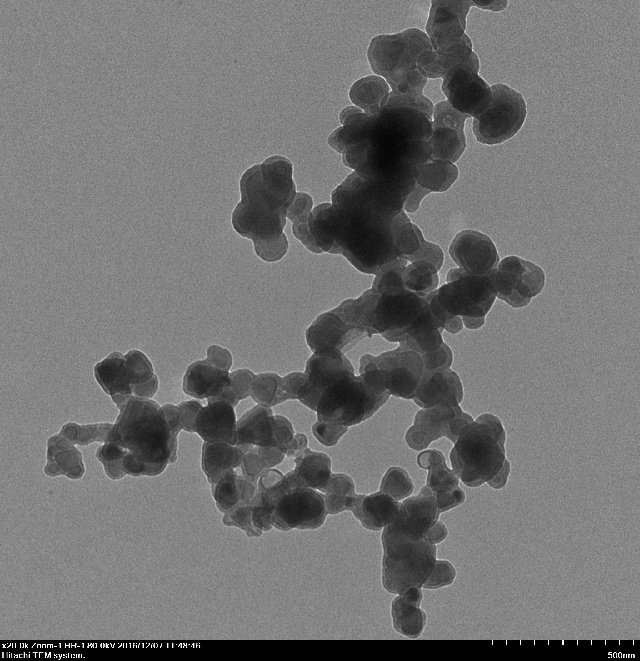

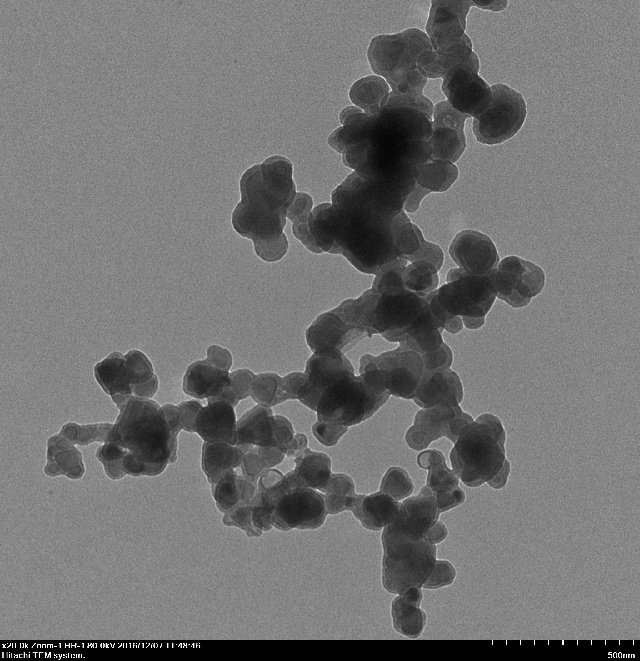

1.High purity, small particle size, uniform distribution, large specific surface area,

2.High surface activity, low bulk density, excellent mechanical, thermal, electrical and chemical properties

3.High hardness, high wear resistance and good Self-lubricating, high thermal conductivity, low coefficient of thermal expansion and high temperature strength.

2.High surface activity, low bulk density, excellent mechanical, thermal, electrical and chemical properties

3.High hardness, high wear resistance and good Self-lubricating, high thermal conductivity, low coefficient of thermal expansion and high temperature strength.

Applications

Surface treatment of metals and other materials:

(1)Wear-resistant coating: The surface of the tool that requires wear-resistant tools such as tools and molds can be treated to improve wear resistance and increase service life.

(2)Absorbing stealth coating: Nano SiC has strong absorption capacity in the 2-18 GHz frequency range, while the radar's working rate is 1-15 GHz.The nano-SiC applied to military materials such as fighters, bombers and other shell materials to form a coating, can absorb radar waves well and play a stealth role.

Modified high strength nylon alloy new material:The addition of β-SiC to nylon has a tensile strength higher than that of ordinary PA6 by more than 10%, and the wear resistance is improved by more than 2.5 times.

Manufacturing precision structural ceramic devices:Such as sliding bearings used in metallurgy, chemical, machinery, aerospace and energy industries, liquid fuel nozzles, helium, high-power high-frequency molds, semiconductor components and so on.

Preparation of high performance composites:Preparation of metal-based, ceramic-based, polymer-based composite materials

(1)Ceramic matrix composites: SiC composite ceramics are high-quality ceramic materials with high strength, high thermal conductivity, good shock resistance, oxidation resistance, wear resistance and erosion resistance. Widely used in metallurgy, energy, chemical and other industries.

(2)Metal matrix composite: SiC is an effective reinforcement phase for alloys. When the mass percentage of SiC is 1%, the strength effect is good and the tensile strength can reach 391 MPa.

(3)Polymer-based composites: The wear resistance of nano-SiC-filled polymer composites is nearly 4 times higher than that of unmodified resins, the friction coefficient is reduced by 36%, the tensile modulus is improved by 44.9%, and tensile strength is increased by 15.8%.

Modified special engineering plastics polyetheretherketone (PEEK) wear resistance:The nano-silicon carbide surface-treated with the coupling agent can greatly improve and improve the wear resistance of PEEK when the addition amount is about 5 ‰ to 1%.

Metal surface such as composite nickel plating:

(1)Metal plating: nickel is used as the matrix metal, and SiC particles are added to electroplate the metal plated parts. The micro-hardness of the composite plating layer is greatly improved, the wear resistance is improved by 3-5 times, the life is improved by 2-4 times, and the plating layer and the substrate are The bonding strength is increased by 30-40%, the covering ability is strong, and the plating layer is uniform, smooth and delicate.

(2)Plastic plating: The hardness of the coating is 2.68 times that of the pure nickel layer, and the wear resistance is 4.1 times that of the pure nickel layer. The bonding strength of the coating is good, and no blistering, cracking or falling off occurs.

Application in rubber tires: adding a certain amount of nano-silicon carbide can be modified without changing the original rubber formula, and its wear resistance can be increased by 15%-30% without reducing its original performance and quality. In addition, nano-silicon carbide is used in rubber rubber rollers, printer fixing films and other rubber products such as wear-resistant, heat-dissipating and temperature-resistant.

Silicon carbide is used in special plastics: PI (polyimide), PEEK (polyether ether ketone), PTFE (polytetrafluoroethylene) and other special plastics, which will be widely used in PE, PVC, PA, PP, PS, PC, PET, PBT, ABS, POM, PPO, PPS and other fields, comprehensively improve the wear resistance, thermal conductivity, insulation, tensile impact, high temperature resistance and thermal expansion coefficient of plastics.

Electrical appliances: Composite plating is used to form a thin layer of Au-SiC composite coating with excellent composite performance on the base of copper alloy or other metal materials. It is used on the contacts of the relay to greatly improve the reliability and service life of the relay. .

Application in Lubricating Grease: Nano-SiC is quickly integrated into various oils and fats. It can form a nano-protective film on the metal surface, which can greatly reduce the friction and make the friction coefficient almost close to zero. Magical features. In addition, this material provides physical nano-plating of the worn metal surface to repair wear.

Other areas: high-performance structural ceramics (such as rockets, nozzles, nuclear industry, etc.), absorbing materials, anti-wear grease, high-performance brake pads, high-hardness wear-resistant powder coatings, composite ceramics toughen and so on.

(1)Wear-resistant coating: The surface of the tool that requires wear-resistant tools such as tools and molds can be treated to improve wear resistance and increase service life.

(2)Absorbing stealth coating: Nano SiC has strong absorption capacity in the 2-18 GHz frequency range, while the radar's working rate is 1-15 GHz.The nano-SiC applied to military materials such as fighters, bombers and other shell materials to form a coating, can absorb radar waves well and play a stealth role.

Modified high strength nylon alloy new material:The addition of β-SiC to nylon has a tensile strength higher than that of ordinary PA6 by more than 10%, and the wear resistance is improved by more than 2.5 times.

Manufacturing precision structural ceramic devices:Such as sliding bearings used in metallurgy, chemical, machinery, aerospace and energy industries, liquid fuel nozzles, helium, high-power high-frequency molds, semiconductor components and so on.

Preparation of high performance composites:Preparation of metal-based, ceramic-based, polymer-based composite materials

(1)Ceramic matrix composites: SiC composite ceramics are high-quality ceramic materials with high strength, high thermal conductivity, good shock resistance, oxidation resistance, wear resistance and erosion resistance. Widely used in metallurgy, energy, chemical and other industries.

(2)Metal matrix composite: SiC is an effective reinforcement phase for alloys. When the mass percentage of SiC is 1%, the strength effect is good and the tensile strength can reach 391 MPa.

(3)Polymer-based composites: The wear resistance of nano-SiC-filled polymer composites is nearly 4 times higher than that of unmodified resins, the friction coefficient is reduced by 36%, the tensile modulus is improved by 44.9%, and tensile strength is increased by 15.8%.

Modified special engineering plastics polyetheretherketone (PEEK) wear resistance:The nano-silicon carbide surface-treated with the coupling agent can greatly improve and improve the wear resistance of PEEK when the addition amount is about 5 ‰ to 1%.

Metal surface such as composite nickel plating:

(1)Metal plating: nickel is used as the matrix metal, and SiC particles are added to electroplate the metal plated parts. The micro-hardness of the composite plating layer is greatly improved, the wear resistance is improved by 3-5 times, the life is improved by 2-4 times, and the plating layer and the substrate are The bonding strength is increased by 30-40%, the covering ability is strong, and the plating layer is uniform, smooth and delicate.

(2)Plastic plating: The hardness of the coating is 2.68 times that of the pure nickel layer, and the wear resistance is 4.1 times that of the pure nickel layer. The bonding strength of the coating is good, and no blistering, cracking or falling off occurs.

Application in rubber tires: adding a certain amount of nano-silicon carbide can be modified without changing the original rubber formula, and its wear resistance can be increased by 15%-30% without reducing its original performance and quality. In addition, nano-silicon carbide is used in rubber rubber rollers, printer fixing films and other rubber products such as wear-resistant, heat-dissipating and temperature-resistant.

Silicon carbide is used in special plastics: PI (polyimide), PEEK (polyether ether ketone), PTFE (polytetrafluoroethylene) and other special plastics, which will be widely used in PE, PVC, PA, PP, PS, PC, PET, PBT, ABS, POM, PPO, PPS and other fields, comprehensively improve the wear resistance, thermal conductivity, insulation, tensile impact, high temperature resistance and thermal expansion coefficient of plastics.

Electrical appliances: Composite plating is used to form a thin layer of Au-SiC composite coating with excellent composite performance on the base of copper alloy or other metal materials. It is used on the contacts of the relay to greatly improve the reliability and service life of the relay. .

Application in Lubricating Grease: Nano-SiC is quickly integrated into various oils and fats. It can form a nano-protective film on the metal surface, which can greatly reduce the friction and make the friction coefficient almost close to zero. Magical features. In addition, this material provides physical nano-plating of the worn metal surface to repair wear.

Other areas: high-performance structural ceramics (such as rockets, nozzles, nuclear industry, etc.), absorbing materials, anti-wear grease, high-performance brake pads, high-hardness wear-resistant powder coatings, composite ceramics toughen and so on.